Deep Groove Ball Bearing

Classification :

PRODUCT DETAILS

Keywords: Jinan Baxin Industry Trading Company ,.Ltd.

Deep groove ball bearing is a rolling bearing characterized by deep grooves on the outer and inner rings. These deep groove-shaped raceways can accommodate many small steel balls. These steel balls roll between the inner and outer rings, thereby reducing friction, supporting and transferring loads12. Its working principle is based on the principle of rolling friction. When the bearing rotates, the steel ball rolls in the raceway of the inner and outer rings instead of sliding, which can significantly reduce friction and wear and improve mechanical efficiency and speed3.

Deep groove ball bearings are suitable for rotary moving parts of various mechanical equipment, such as low-power motors, automobile and tractor gearboxes, machine tool gearboxes, etc. Deep groove ball bearings have the characteristics of low friction resistance and high rotation speed, and are suitable for occasions where high rotation speed and low friction are required

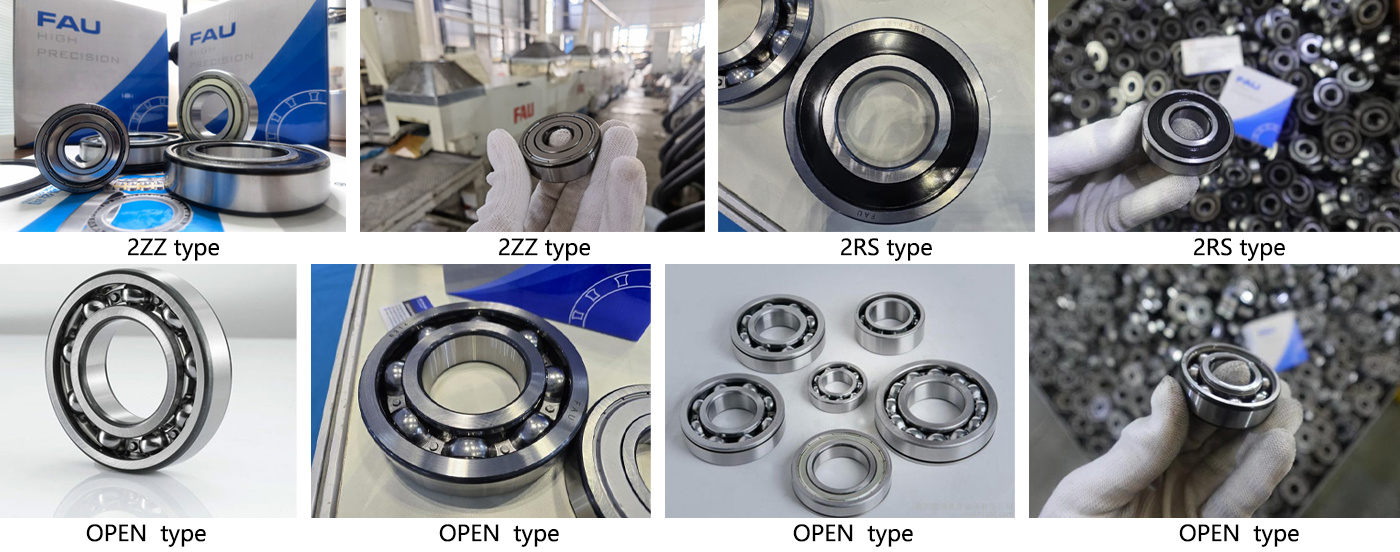

In addition, deep groove ball bearings are available in two types: single row and double row, as well as two structures: seal (2ZZ, 2RS) and open (OPEN).

The deep groove ball grades are divided into: Z0V0 G16, Z1V1 G16, Z2V2 G10, Z3V3 G10, Z4V4 G10, etc. The material is bearing steel (GCR15).

The most common series of deep groove ball bearings are 6000 series, 6200 series, 6300 series and 6400 series. The structural diagrams of deep groove ball bearings and the parameters of each part are as follows:

Product parameters

|

BEARING NO. |

BOUNDARY DIMENSIONS(MM) |

RATED LOAD |

SPEED RATING(IPM) |

WEIGHT(KG) |

||||

|

BASIC LOAD RATING(KN) |

||||||||

|

d |

D |

B |

Cr |

Cor |

|

lubrication |

||

|

6000 |

10 |

26 |

8 |

455 |

1.97 |

22000 |

30000 |

0.019 |

|

6001 |

12 |

28 |

8 |

5.1 |

2.38 |

20000 |

26000 |

0.022 |

|

6002 |

15 |

32 |

9 |

5.58 |

2.85 |

19000 |

24000 |

003 |

|

6003 |

17 |

35 |

10 |

6 |

3.25 |

17000 |

21000 |

0.04 |

|

6004 |

20 |

42 |

12 |

9.38 |

5.02 |

16000 |

19000 |

0.069 |

|

6005 |

25 |

47 |

12 |

10.1 |

5.85 |

15000 |

18000 |

0.08 |

|

6006 |

30 |

55 |

13 |

13.2 |

8.3 |

13000 |

15000 |

0.12 |

|

6007 |

35 |

62 |

14 |

16 |

10.3 |

12000 |

14000 |

0.16 |

|

6008 |

40 |

68 |

15 |

15.34 |

10.85 |

9000 |

11000 |

0.18 |

|

6009 |

45 |

75 |

16 |

21.19 |

14.77 |

8000 |

10000 |

0.24 |

|

6010 |

50 |

80 |

16 |

22.05 |

16.21 |

7300 |

9200 |

0.26 |

|

6011 |

55 |

90 |

18 |

30.97 |

22.52 |

6300 |

8000 |

0.37 |

|

6012 |

60 |

95 |

18 |

31.65 |

24.22 |

6000 |

7500 |

0.39 |

|

6200 |

10 |

30 |

9 |

5.1 |

2.38 |

20000 |

26000 |

0.032 |

|

6201 |

12 |

32 |

10 |

6.82 |

3.05 |

19000 |

24000 |

0.037 |

|

6202 |

15 |

35 |

11 |

7.65 |

3.72 |

18000 |

22000 |

0.045 |

|

6203 |

17 |

40 |

12 |

9.58 |

4.78 |

16000 |

20000 |

0.065 |

|

6204 |

20 |

47 |

14 |

12.8 |

6.65 |

14000 |

18000 |

0.106 |

|

6205 |

25 |

52 |

15 |

14 |

7.85 |

13000 |

15000 |

0.128 |

|

6206 |

30 |

62 |

16 |

19.5 |

11.3 |

11000 |

13000 |

0.199 |

|

6207 |

35 |

72 |

17 |

25.7 |

15.4 |

9200 |

11000 |

0.288 |

|

6208 |

40 |

80 |

18 |

29.5 |

18 |

8000 |

10000 |

0.368 |

|

6209 |

45 |

85 |

19 |

31.5 |

20.5 |

7000 |

9000 |

0.416 |

|

6210 |

50 |

90 |

20 |

35 |

23.2 |

7100 |

8500 |

0.5 |

|

6211 |

55 |

100 |

21 |

43.5 |

28.8 |

6300 |

7500 |

0.61 |

|

6212 |

60 |

110 |

22 |

53 |

33 |

5600 |

7100 |

0.79 |

|

6300 |

10 |

35 |

11 |

7.65 |

3.48 |

18000 |

24000 |

0.053 |

|

6301 |

12 |

37 |

12 |

9.72 |

5.08 |

17000 |

22000 |

0.06 |

|

6302 |

15 |

42 |

13 |

11.5 |

5.42 |

16000 |

20000 |

0.082 |

|

6303 |

17 |

47 |

14 |

13.5 |

6.58 |

15000 |

18000 |

0.115 |

|

6304 |

20 |

52 |

15 |

15.8 |

7.88 |

13000 |

16000 |

0.142 |

|

6305 |

25 |

62 |

17 |

20.6 |

11.3 |

11000 |

13000 |

0.232 |

|

6306 |

30 |

72 |

19 |

26.7 |

15 |

6600 |

12000 |

0.346 |

|

6307 |

35 |

80 |

21 |

33.4 |

19.3 |

8500 |

10000 |

0.457 |

|

6308 |

40 |

90 |

23 |

40.8 |

24 |

7000 |

8500 |

0.639 |

|

6309 |

45 |

100 |

25 |

52.8 |

31.8 |

6300 |

7500 |

0.837 |

|

6310 |

50 |

110 |

27 |

62 |

38 |

6300 |

7500 |

1.07 |

|

6311 |

55 |

120 |

29 |

71.5 |

45 |

5600 |

6700 |

1.39 |

|

6312 |

60 |

130 |

31 |

82 |

48.5 |

5300 |

6300 |

1.71 |

Product Series

QUALITY INSPECTION

We focus on researching ,manufacturing and sales of bearings with a workshop area of more than four thousand square meters ,equipped with modern production equipment ,CNC automatic production line and advanced testing instruments.

PACKAGING AND SHIPPING

Packaging and Shipping

Packaging and Shipping

Packaging and Shipping

Packaging and Shipping

Packaging and Shipping

Packaging and Shipping

CUSTOMER VISIT

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

APPLICATION FIELD

Petrochemical

Mine

Metallurgy

High Speed Rail

Car

Aviation

FAQ

Q: Can I visit your factory?

Q: Can we take some samples? Any fees?

Q:Can you deliver the goods on time?

Q: What are the loading ports?

Q: Is there quality inspection before loading?

Q: How is the product packaged?

RELATED PRODUCTS

In addition, deep groove ball bearings are available in two types: single row and double row, as well as two structures: seal (2ZZ, 2RS) and open (OPEN) The deep groove ball grades are divided into: Z0V0 G16, Z1V1 G16, Z2V2 G10, Z3V3 G10, Z4V4 G10, etc. The material is bearing steel (GCR15)

Tapered roller bearings have a wide range of applications, including automotive, aerospace and mining inclined fields.

High temperature resistance and impact resistance, high load-bearing capacity, high speed and low temperature rise and long service life The grades of center-aligning roller bearings are divided into: P0, P6, P5, P4, etc. The material is bearing steel (GCR15) The series of center-aligning roller bearings include E1, MA, MB, CC, E, CA and other series

The design of the outer spherical bearing with seat is cleverly designed, combining the advantages of the outer spherical bearing and seat cushion, and can perform excellent performance in a variety of machinery and equipment. Its structure is simple, easy to install and replace, and usually has oil injection holes for easy lubrication and daily maintenance. In addition, the outer spherical bearing with seat has good centering ability and can automatically adjust the axis deviation caused by installation errors or shaft bending to ensure the smooth operation of the equipment.

Cylindrical roller bearings have the characteristics of strong load-bearing capacity, wide application range, high precision and low friction. It is widely used in machine tool spindles, high-frequency motors and gas turbines, bike and differential pinion shafts, as well as steel rolling and crushers, providing them with stable support and load-bearing capacity and able to withstand high loads and impact loads.

The main function of the self-aligning ball bearing is to automatically compensate for the centering error between the shaft and the bearing seat, bear radial loads and partial axial loads, and is suitable for mechanical systems where the shaft is easy to bend or difficult to center.

GET A FREE QUOTE